Dear Kelloists,

First things first, we wish you a very happy new year, filled with countless great nights of sleep!

We’ve been working all December to prepare the manufacturing of Kello. Here’s a roundup of our progress.

Design For Manufacturing

The engineers at our factory spent the last 3 weeks perfecting the design of Kello to improve manufacturability and assembly.

We’re currently in a validation phase to make sure everything fits nicely inside Kello. Last week, we made another prototype to validate the changes from the design for manufacturing phase.

Kello ready-for-production prototype

We were very pleased by this prototype, especially by the feel of the “snooze” button: as you know, the whole shell of Kello acts a one big button and we want to:

- provide good tactile feedback when pressing the button,

- make sure you can easily press anywhere on the shell (front/back/center/right/left) to “snooze”.

Our engineers did a great job, and the mechanical feedback of the button is really satisfying. We still have a few refinements to do, in particular we want to narrow the gap between the shell and core of the device.

The Microcontroller Dilemma

Like every smart device, Kello has a motherboard with a microcontroller chip that basically acts as the brain of the device (just like the microprocessor inside your phone or your computer).

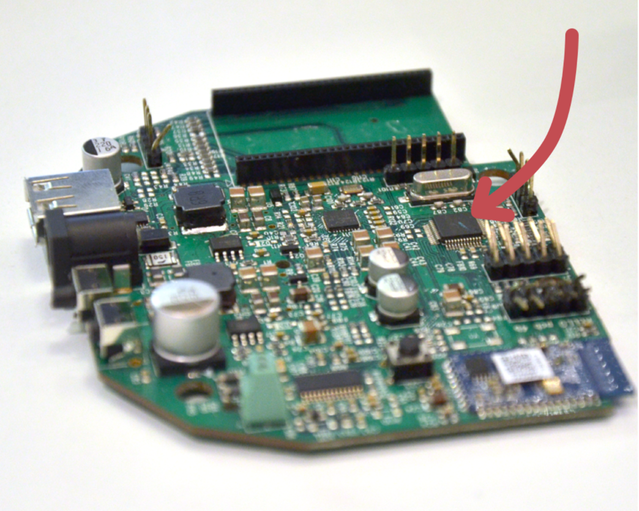

Kello’s motherboard and microcontroller (red arrow)

When starting the design of Kello, we chose a microcontroller we thought would fit our needs. As we refine the future of Kello however, we realized that it might not be powerful enough to do everything we want to do.

While the current controller is enough to deliver everything we promised on Kickstarter, we have a roadmap for more Sleep Programs that will need some additional power.

So we faced a dilemma: keep the old microcontroller that we validated with a dozen of prototypes, or upgrade it with a more powerful version, spend a few weeks making and validating the new design, and change the firmware to make it compatible?

It was a tough choice. As we’re committed to deliver the best Kello we can, we chose to upgrade the microcontroller.

This means that we’re currently redesigning a part of the motherboard. This change will have an impact on Kello’s shipping date, which will be postponed to May 2017 instead of late March 2017.

We’re sorry for this delay but we feel making a “future-proof” Kello we can upgrade remotely with new features is crucial for making the best product for you.

If you have any question on why we changed the microcontroller, feel free to reply to this update!

New LED screens

In parallel of the redesign, we have sourced Kello’s key components. During the previous weeks we have secured the LED panels.

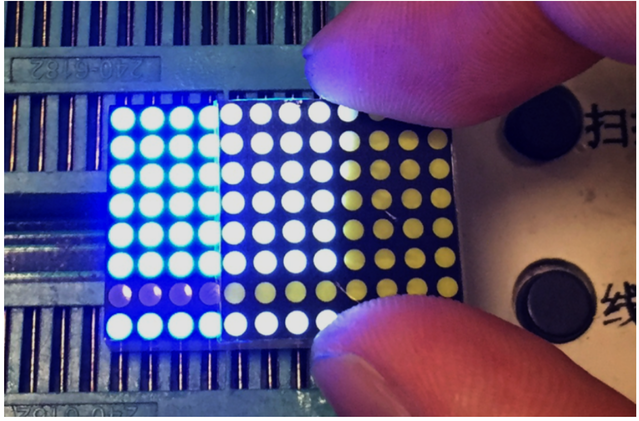

We’ll use a fairly new technology: blue LEDs covered by a special sticker that converts the emitting color from blue to white. It’s pretty impressive to see in person.

On the left on the picture is the screen without the filter, and on the right is the screen with the filter

The benefits of such a technology are:

- Nice, warm white color,

- High longevity (100,000+ hours),

- High dimmability.

We’re currently testing these screens to make sure they’re reliable.

Next Steps

As of now, our next steps are:

- order all of the components to make 3000+ Kellos (microcontrollers, Wi-Fi and Bluetooth modules, screens...),

- start manufacturing the steel tools needed to inject the plastic parts.

All of this has to be done before the Chinese New Year (China’s 1-month holiday shutdown, starting Jan 20). January will be a big month for Kello, and as always, we’ll keep you updated every step of the way.

Thanks for your incredible support,

The Kello Team