Dear Kelloists,

We’re so excited! We’ve finally started the very first step of mass production (plastic injection), and are moving very fast towards the next stages of mass manufacturing (circuit boards and assembly).

Plastic Injection

Stuff’s getting real. Following our timeline, last Wednesday we started injecting the plastic parts of all units.

Plastic injection is the very first part of mass producing for most consumer electronics products. High temperature plastic (250 °C/480 °F) is injected with high pressure in big steel moulds in order to shape plastic parts that will later be assembled into the final product.

It was so exciting to see Kellos coming out of these huge injection machines. Check out the video below to have a peek at the whole process!

Some trivia facts:

- Our plastic factory also makes some of the critical gear parts of some major German automotive brands (=we’re in good hands).

- They can inject the plastic parts of up to 500 Kellos per day. It takes 42 seconds for each coloured shell to be injected: this is unusually long because the shell is very thick and the surface quality of this part is critical.

- After coating the shell with the Soft Touch layer, each part must be cured in a oven for 40 minutes!

Photo gallery of our visit:

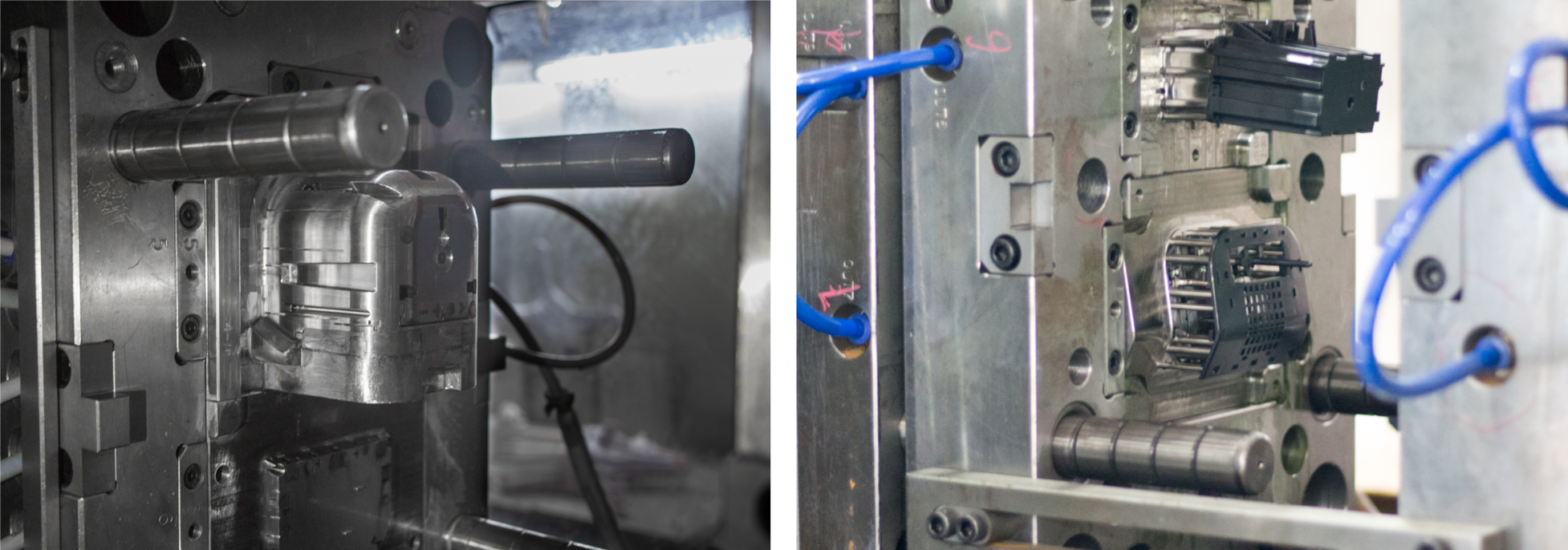

Molds, molds, molds

The molds of Kello’s core and front panel

Parts that are ready to go to the next stage

Plastic chips pool!

The cemetery of the parts that didn’t meet our quality standards (fortunately this plastic will be recycled)

Next Step: Circuit Boards

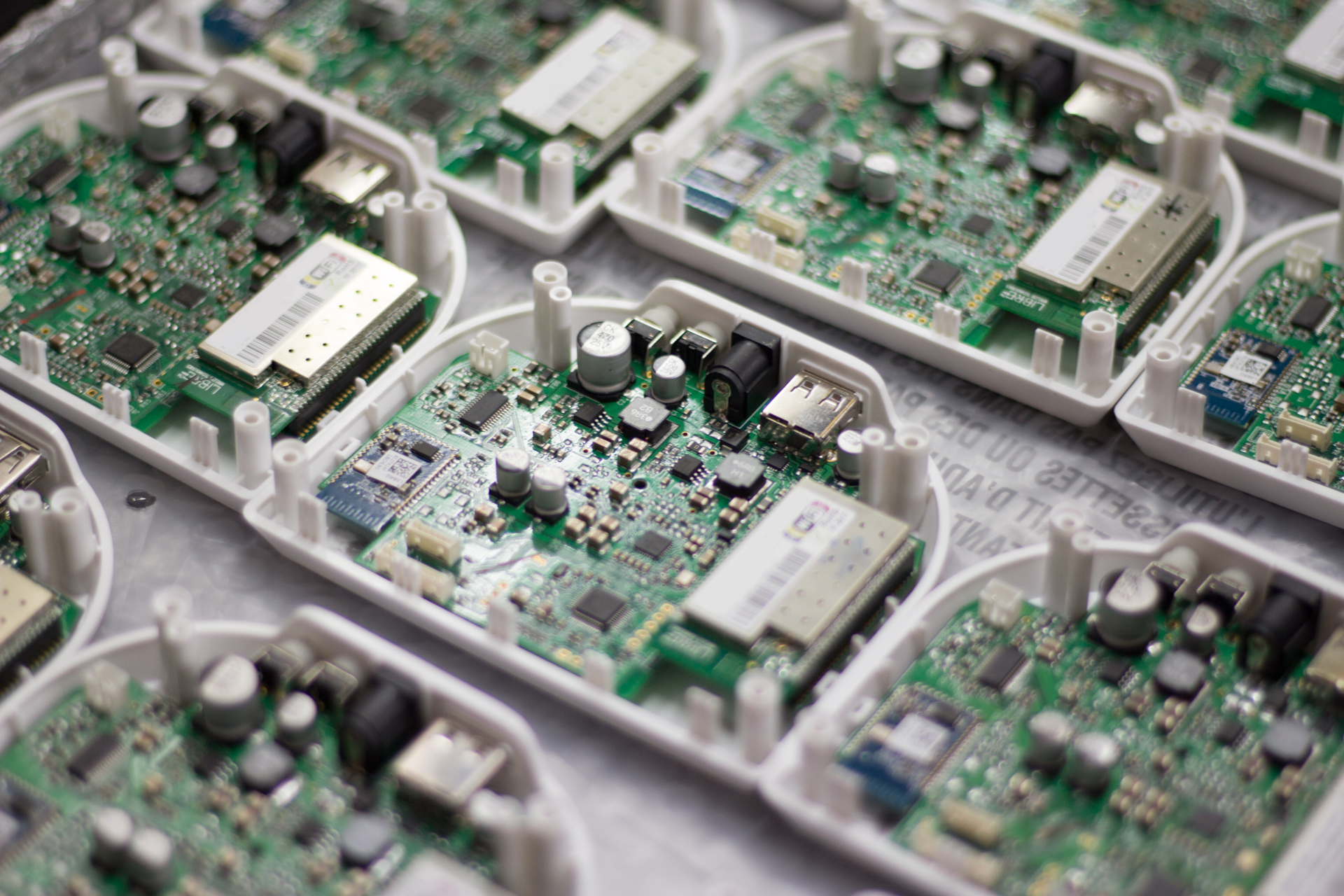

Plastic injection is moving along fast and should be finished next week. Meanwhile, we’re working on the printed circuit boards but we hit a speed bump.

In order to make Kello’s motherboard, our factory has to solder hundreds of tiny componentson a circuit board using high-precision pick&place robots. But first, they have to actually make the base circuit board and this step took a bit longer than expected because of the complexity of our motherboard. The matter is resolved now and we expect to receive the boards this coming Monday.

Kello motherboards

Timeline

Let’s talk dates. We don’t want to commit on hard dates just yet because so many things can happen, especially with the circuit boards being slightly delayed. However, we’re confident that shipping will start in the first half of July. We’ll know more in the upcoming days.

After manufacturing the plastic parts and the circuit boards, the last step to assemble the two, test that everything works perfectly and put the product in its box. This assembly phase will start in the upcoming days and, by the end of the month, we’ll have 30 units that we’ll inspect one by one before moving to mass assembly of all units. These pre-production samples help fine-tune the actual production process, and the resulting product will be commercial grade (= exactly the same as the production product).

In Other News...

Packaging

Packaging is validated. We received a few days ago the prototypes of the boxes and we’re very happy with the result:

We think it’s simple, beautiful, and to the point, just like Kello. But good looks aren’t enough, it also has to be sturdy and protect the unit no matter what. That’s why we tried to put them under a lot of stress. Check for yourself:

Apps

Good news: the iOS app has been validated by Apple. It’s ready to be published on the App Store. For now we’re keeping it private for our internal testing but as soon as we start shipping, you will be able to download it on your iPhone.

The Android app is also making great progress, and we’re testing it every day.

Shipping Preparation

We’ve hand-picked the courier for each 66 countries we’re shipping to, and our third party logistics vendor is ready to ship more than 2,800 boxes. More info in the next update!

That’s it for today. We’re so excited to bring these babies to your home! We’re almost there, it’s the very last stretch and you won’t have to wait too long before having your own Kello on your bedside.

Until then, don’t hesitate to give us a shout-out on hello@getkello.com.

Cheers,

The Kello Team.